We occasionally receive questions to clarify the difference between our Incident Investigation training course and our RCA Facilitator course so we thought we would address some of the most commonly asked questions in this Q&A-style article. We hope you find it helpful. And if you have any questions, as always, please don’t hesitate to contact us.

How is the “Incident Investigation” course different from the “RCA Facilitator” course?

The Incident Investigation course covers the process of identifying, obtaining, documenting, and preserving the raw data related to an incident, then constructing a general timeline of the incident.

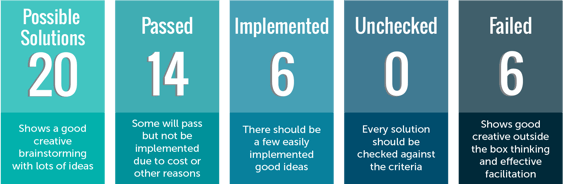

The RCA Facilitator course then trains our students on how to sort through this data using cause and effect principles to identify causes that are relevant and formulate workable solutions, or preventative measures, to prevent recurrence. There is also emphasis in the RCA Facilitator course on facilitation skills necessary to conduct the Apollo Root Cause Analysis methodology process.

What are the benefits of the Incident Investigation course?

Without truly understanding the key elements and possessing the necessary skills to conduct a thorough, effective investigation, people run the risk of missing key causal factors of an incident while conducting the actual analysis. This could potentially result in not identifying all possible solutions including those that may be more cost effective, easier to implement, or more effective at preventing recurrence. The Incident Investigation course equips students with the knowledge and skills to conduct a proper investigation to prevent this from happening.

Why it is important for people to attend the Incident Investigation course?

Students will learn the key elements and develop the skills necessary to conduct and document a thorough, effective investigation ensuring all the pertinent information is available for the actual root cause analysis process.

Students will learn:

- The nature of undesirable incidents and why they often repeat

- The value of a thorough, effective investigation – Why spend the time?

- Investigation lead and team selection – Matching individual traits and skill sets to the needs of the investigation

- The roles, or functions that must be filled to ensure thoroughness and reliability of data

- Possible sources of incident information and how to optimize the value and reliability of incident facts and evidence

- Demonstrations of misconceptions about the reliability of evidence and how to avoid them

- Critical interviewing skills for discovering valuable incident information without inadvertently tainting the outcome

- Options to ensure timely incident response so that valuable evidence can be preserved and collected

- The value of developing and using standard templates for use throughout the investigation process

- How to create an incident timeline using multiple sources of information

- Importantly, scaling the investigation effort based on the significance of the incident to avoid wasting precious resources while ensuring investigation thoroughness

- Hands-on individual and group exercises for practicing the key elements of the knowledge and skills listed above

Are there any prerequisites for the Incident Investigation course?

No. Students can take the Incident Investigation course on its own, or combine it with the RCA Facilitator course if they wish to learn the ins-and-outs of the Apollo Root Cause Analysis methodology as well. The Incident Investigation course is designed to stand on its own and depending on a person’s role, they may only need to attend one or the other, or both.

Is there an option to train my team in Incident Investigation via a private, onsite course?

Yes. We can work with a team within a company and create a customized Incident Investigation training course that takes into account their specific processes, triggers, industry, regulations, goals, stats of their HSE incidents, and incident severity tiers, and develop a course to their definitions and templates that can then be used to train staff across the company.

For more information, please contact us.

1. How many injuries have been recorded at your location(s) in the past year?

1. How many injuries have been recorded at your location(s) in the past year?

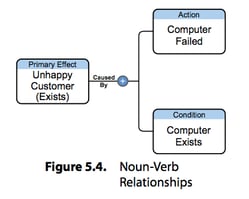

One colleague stated that another must understand this concept since he has an engineering background, and all engineers would know this. I had to inform them that I also have a 30-year background in engineering,

One colleague stated that another must understand this concept since he has an engineering background, and all engineers would know this. I had to inform them that I also have a 30-year background in engineering,